Technical Capabilities

Weight Range:- 0.050 to 250.00 Kilograms weight per piece.

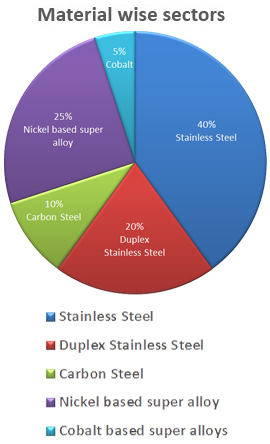

Materials Poured at RTCPL :

| |

ASTM |

DIN |

| Carbon Steel |

A216 - WCB |

1.0619 |

| A216 - WCC |

|

| A352 - LCC |

1.1138 |

| A352 - LCB |

|

| |

|

| Low Alloys Steels |

A217 - WC1 |

1.5419 |

| A217 - WC4 |

|

| A217 - WC5 |

|

| A217 - WC6 |

1.7356 |

| A217 - WC9 |

1.7379 |

| A217 - WC11 |

|

| A217 - C5 |

1.7363 |

| A217 - C12 |

|

| A217 - C12A |

|

| |

|

|

| Martensitic Steels |

A743 - CA15 |

1.4008 |

| A743 - CA40 |

1.4028 |

| A743 CA-6NM |

1.4313 |

| |

|

|

| Heat Resisting Steel |

A297 - HF |

1.4825 |

| A297 - HH |

1.4837 |

| A297 - HI |

1.4846 |

| A297 - HK |

1.4848 |

| |

1.4749 |

| A297 - HD |

1.4823 |

| |

|

|

| Austenitic Stainless Steel |

A351 - CF8 |

1.4308 |

| A351 - CF8M |

1.4408 |

| A351 - CF3 |

1.4306 |

| A351 - CF3M |

1.4404 /

1.4409 |

| A351 - CF8C |

1.4827 |

| A351 - CF10 |

1.4308 |

| A351 - CK20 |

1.4843 |

| A351 - CH20 |

|

| A351 - CN7M |

1.4500 |

| A351 - CG8M |

1.4431 |

| A351 - CG3M |

|

| |

ASTM |

DIN |

| Austenitic Ferrite Duplex Steels |

A351 - CF3MN |

1.4435 |

| A351 - CD4MCu |

|

| A351 - CG6MMN |

1.3964 |

| A351 - CK3MCuN |

|

| |

|

|

| Super Duplex Stainless Steel |

A890 - GR1A |

|

| A890 - GR2A |

|

| A890 - GR3A |

|

| A890 - GR4A |

|

| A890 - GR5A |

|

| A890 - GR6A |

|

| |

|

| Nickle Based Super Alloys |

A494 - M-35-1 |

2.4365 |

| A494 - M-35-2 |

|

| A494 - M 30 C |

|

| A494 - N-12MV |

|

| A494 - N-7M |

|

| A494 - CY40 |

2.4816 |

| A494 - CW12MW |

2.4686 |

| A494 - CW6M |

|

| A494 - CW2M |

2.4610 |

| A494 - CW6MC |

2.4856 |

| A494 - CX2MW |

2.4602 |

| A494 - Cu5MCuC |

2.4858 |

| A560 - 50Cr50Ni |

|

| A560 - 50Cr50Ni-Nb |

2.4813 |

| A560 - 60Cr40Ni |

|

| |

|

|

| Cobalt Based Alloys |

Castings can be supplied as per equipment DIN, JIS, BS and GOST standards.

Other than above, in general we can cast any material compositions as per customers specifications meeting international standards.

Investment castings tolerances

Reference international standard: VDG P690

Linear Tolerances :

Nominal size

mm |

D1 Tolerance

(general dimensions) |

D2 Tolerance

(some functional

dimensions) |

| 0 to 6 |

±0.15 |

±0.12 |

| 6 to 10 |

±0.18 |

±0.14 |

| 10 to 18 |

±0.22 |

±0.17 |

| 18 to 30 |

±0.26 |

±0.20 |

| 30 to 50 |

±0.40 |

±0.31 |

| 50 to 80 |

±0.45 |

±0.37 |

| 80 to 120 |

±0.55 |

±0.44 |

| 120 to 180 |

±0.8 |

0 ±0.65 |

| 180 to 250 |

±1.20 |

±0.95 |

| 250 to 315 |

±1.30 |

±1.10 |

| 315 to 400 |

±1.80 |

±1.40 |

Tolerance for straightness, flatness, parallelism, shape :

| Precision class |

Length of the tolerated element |

| to 25 mm |

25 to 50 mm |

up to 50 mm |

| allowed difference |

| D1 |

0.15 mm |

0.25 mm |

0.6% |

| D2 |

0.10 mm |

0.20 mm |

0.4% |

Tolerance for angle values and right angles :

| Precision class |

Nominal dimensions |

| |

to 30 mm |

30 to 100 mm |

100 to 200mm |

up to 200mm |

| D1 |

allowed deviation |

| minute degree |

30 |

30 |

30 |

20 |

| mm / 100 mm |

0.87 |

0.87 |

0.87 |

0.58 |

| D2 |

allowed deviation |

| minute degree |

30 |

20 |

15 |

15 |

| mm / 100 mm |

0.87 |

0.58 |

0.44 |

0.44 |

Surface quality according to ISO R 468, DIN 4769 and VSM10321 :

| |

Ra |

Rz |

Rt |

| N9 |

6.3 |

23-32 |

25-38 |